![]()

TECHNICAL UPDATES

Squeeze Tube Compatibility

The most critical component of a peristaltic pump is the squeeze tube. While it may look like a simple "rubber hose" it performs the rugged task of repeated compression and expansion to move liquid through it. A squeeze tube must perform this task very consistently to provide accurate flow rates and long term reliability. Knight squeeze tubes are custom made of proprietary materials with a strong focus on inside/outside diameter tolerances. Our attention to quality by checking every squeeze tube ensures a correct fit and consistent operation for new systems, or for tube replacements.

Under normal operation, a squeeze tube will typically last about 6 months. If a chemical aggressively attacks the tube, it will cause the tube to either harden or turn spongy, which greatly reduces its usable life. To meet the diverse needs of the chemical industry, we offer squeeze tubes made from a variety of elastomers. The table below provides general compatibility guidelines for the different types of squeeze tubes available from Knight. The "type" column refers to the suffix letter of the tube model.

Examples: T-50-E T-66-M T-86-T

Type Color Description E Black A resilient tube with excellent memory. Compatible with weak to strong alkalis, and weak to medium acids. M White A silicone-based tube good for most bases and acids. Not suitable for solvents or oils. T Beige A strong industrial-strength tube with superior acid-resistant and alkali-resistant qualities. D Black Similar to the "T" tubing in strength and resistive qualities. F Black A fluoro-viton tubing used for strong solvents and acids.

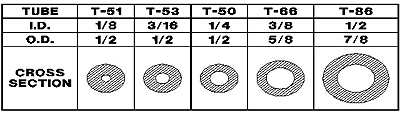

The following table is provided for identification of the five most popular squeeze tube sizes used in Knight pumps. The measurements shown are the closest fractional value (inches) for reference.